Introduction to IPC-A-610

An early Christmas gift arrived at Stratify Labs today: the latest revision of the IPC-A-610 standard. At Stratify Labs, we like to stay up to date with the most current industry guidelines for building and designing electronic assemblies. PCB design plays a big part in ensuring a smooth transition from prototyping to production and long term reliability.

An early Christmas gift arrived at Stratify Labs today: the latest revision of the IPC-A-610 standard. At Stratify Labs, we like to stay up to date with the most current industry guidelines for building and designing electronic assemblies. PCB design plays a big part in ensuring a smooth transition from prototyping to production and long term reliability.

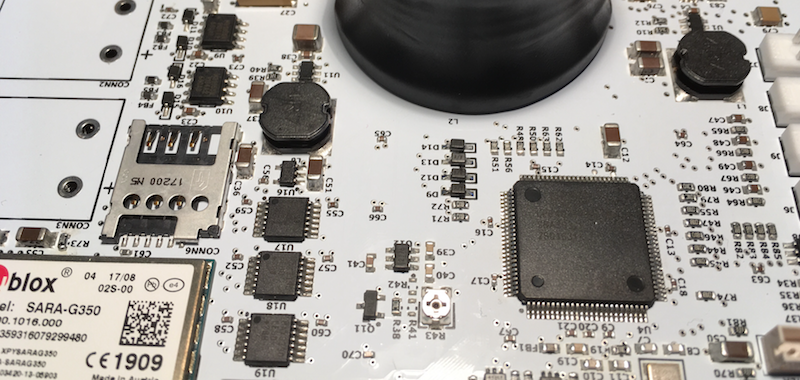

This blog post will be the first in an ongoing series of practical PCB design tips. Even if you are not an engineer, it is important to know you are hiring the right engineers and contract manufacturers. These tips will help you spot red flags from both a design and manufacturing perspective.

IPC Classes

The first thing to understand about IPC-A-610 is its classification system:

- Class 1: General Electronic Products

- Class 2: Dedicated Service Electronic Products

- Class 3: High Performance/Harsh Environment Electronic Products

Class 1 is the least rigorous and includes PCBs that would go in toys or other products where failure is not a big deal.

Class 2 is more rigorous and includes most industrial products and consumer appliances. Products where uninterrupted service is important but not critical.

Class 3 is the most rigorous and includes high performance products where performance is critical and the operating environment may be particularly harsh. These products include many medical devices, military equipment, as well as aerospace and automotive assemblies.

Bottom Line

If you are building a product, you will need to understand how your PCB needs to perform and in what environment so that you can tell your contract manufacturer which IPC class is required. When selecting a class, keep in mind more rigorous means more expensive.